About

Important

This project is under construction. New functionalities are constantly added to this package. The project is directly related to the study [Schott2023].

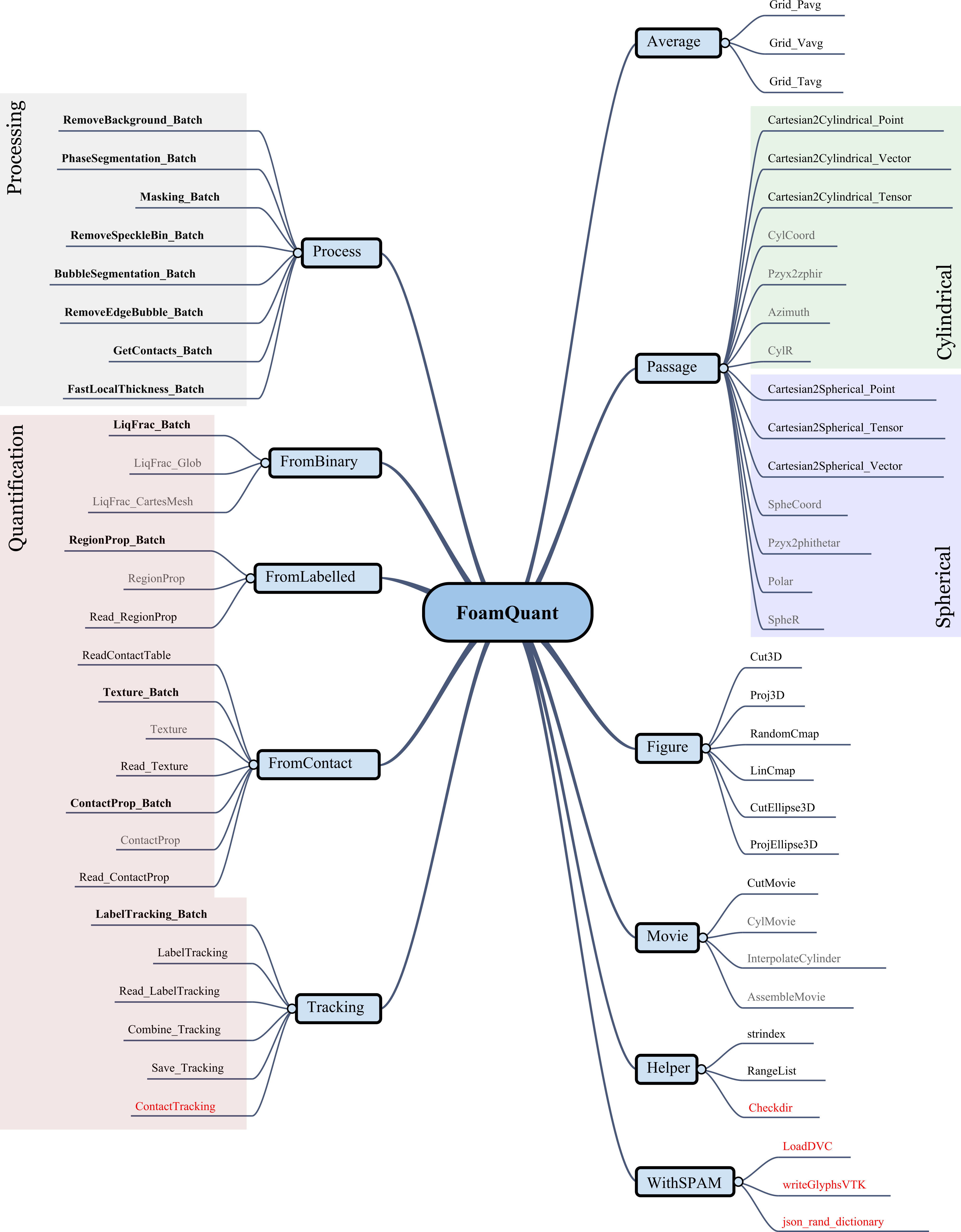

Overview

Current package structure. The functions in red are not yet included in the package.

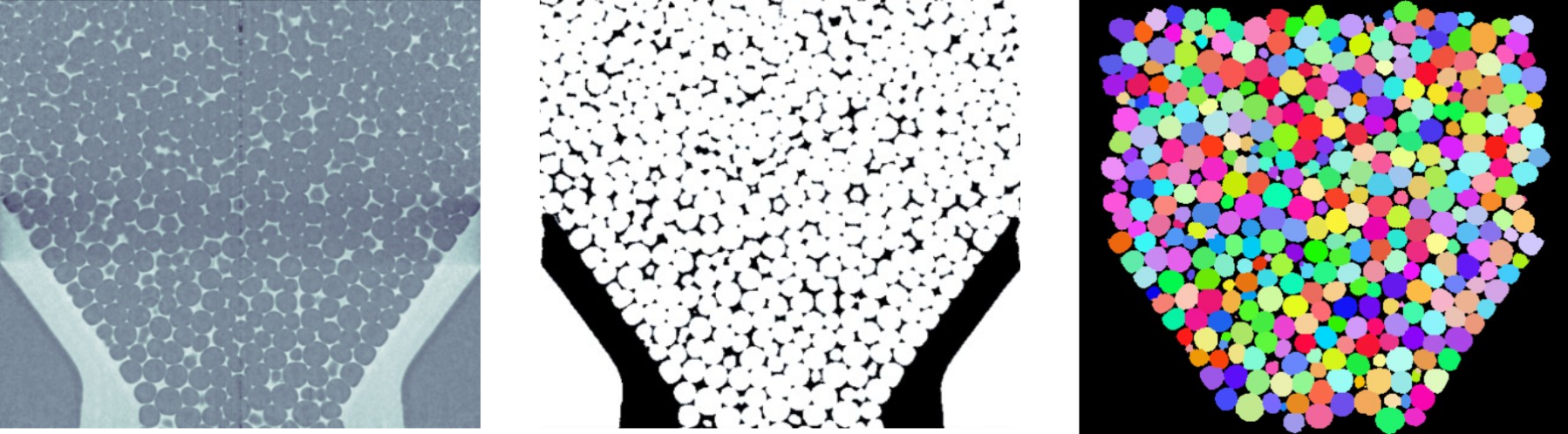

Process

Functions for processing batch liquid foam images, all the steps from the raw-reconstructed images to the labelled images :

Remove background (homogeneization)

Phase segmentation (binarization)

Masking (cylindrical or region of interest)

Remove small objects and holes (volume threshold)

Bubble segmentation (watershed)

Remove edge bubbles (edge of a mask if provided)

From the left to the right: raw, phase segmented and bubble segmented images.

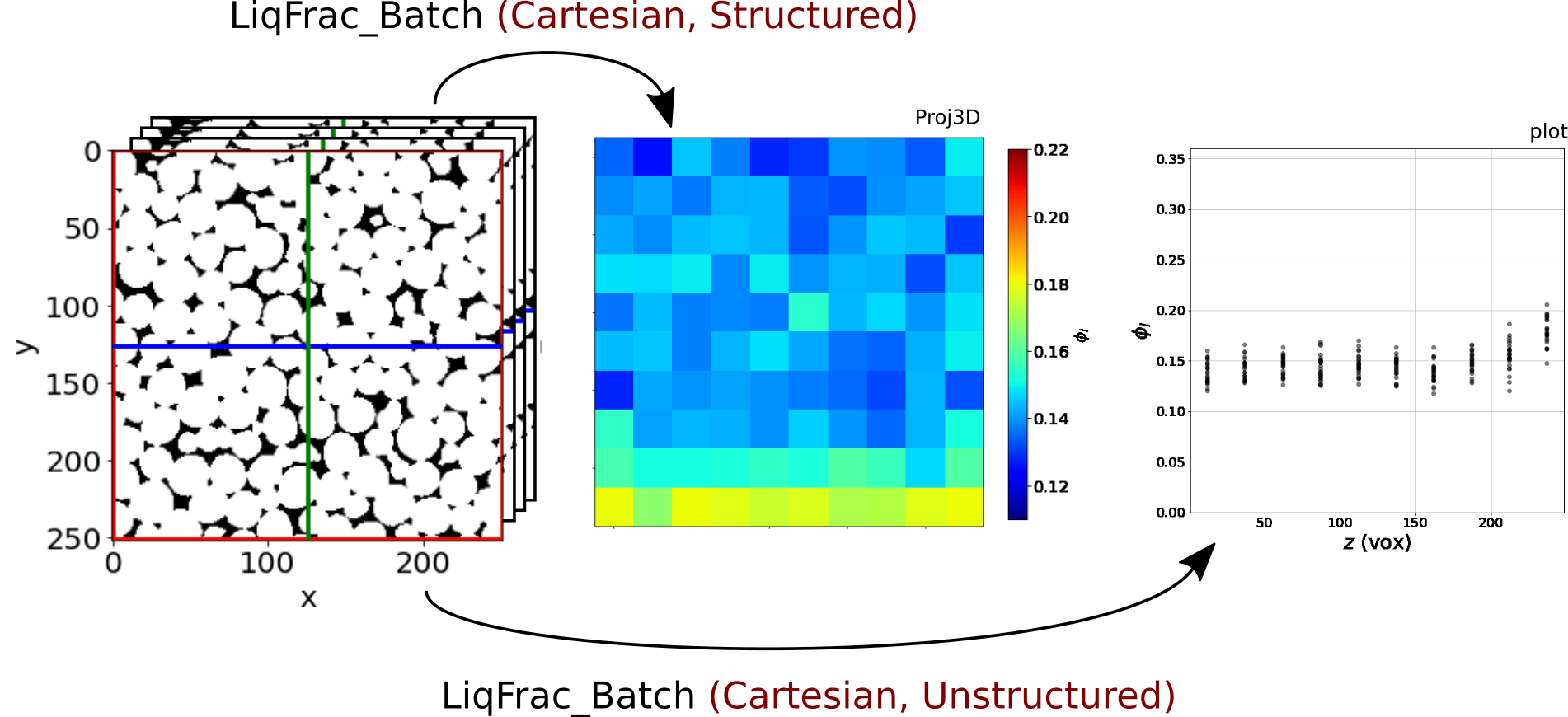

FromBinary

Functions to quantify the liquid fraction from a batch of phase segmented images.

The liquid fraction along a cartesian mesh can be returned structured or unstructured.

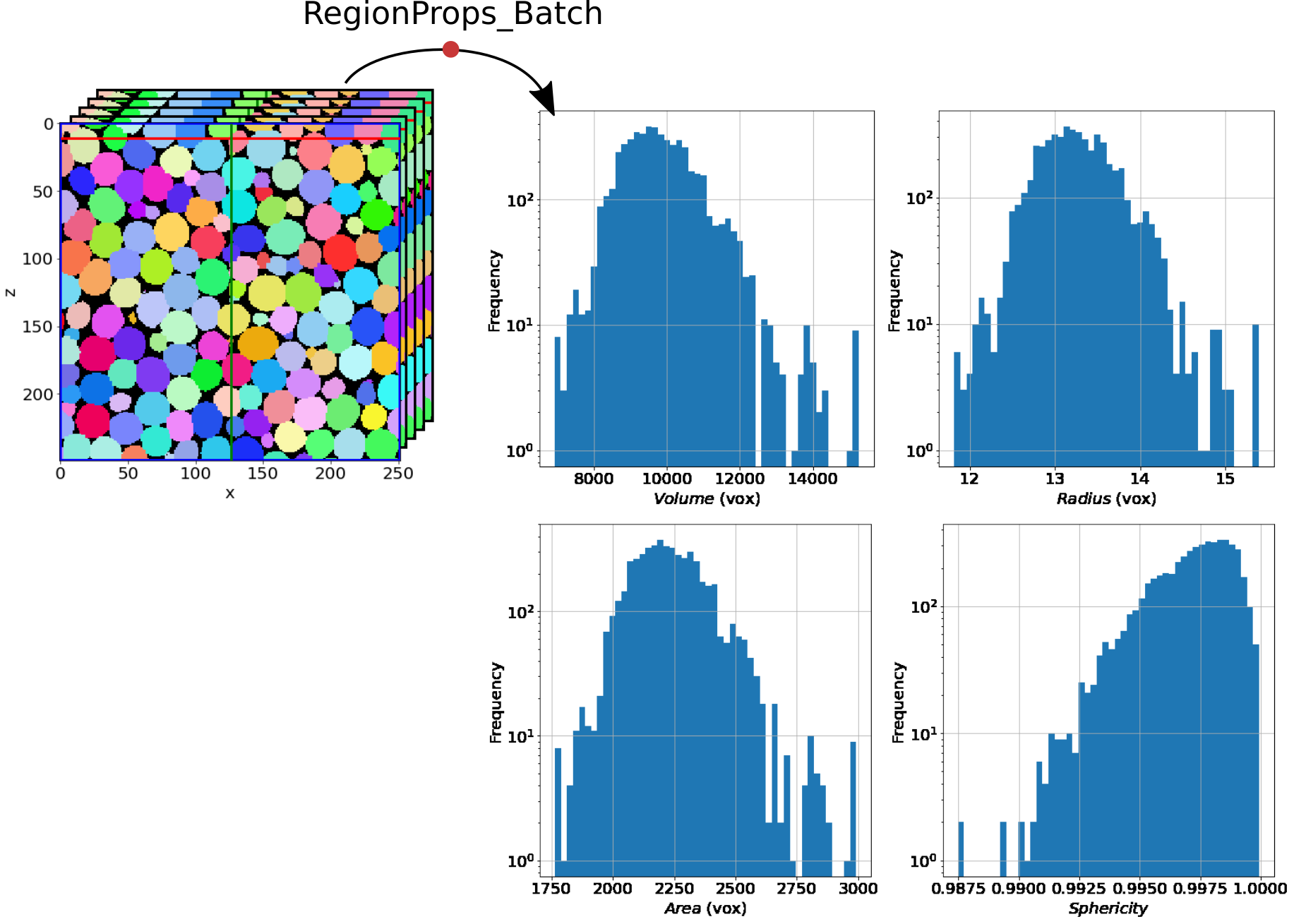

FromLabelled

Functions to quantify the bubbles regions properties from a batch of labelled images.

The function save the regions properties in a .csv

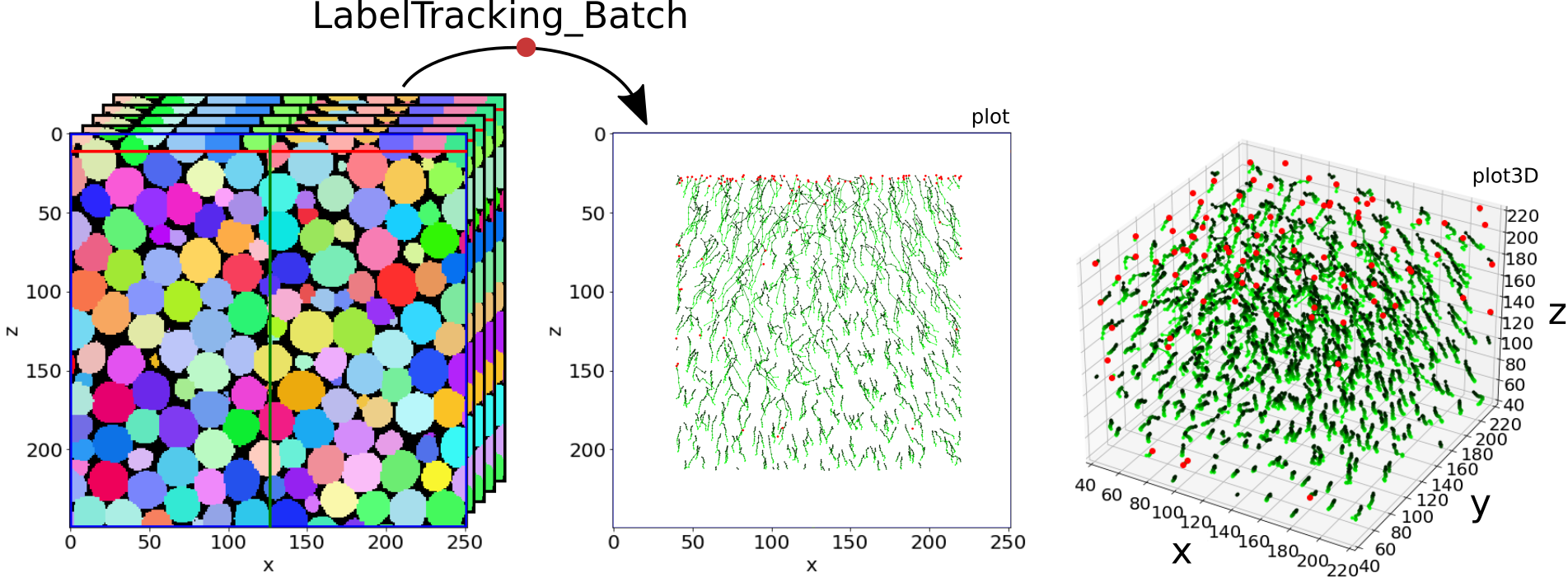

Tracking

Functions to track the bubbles and their properties from a batch of labelled images.

The color (from green to black) indicates the time index. The red points are the lost tracking positions.

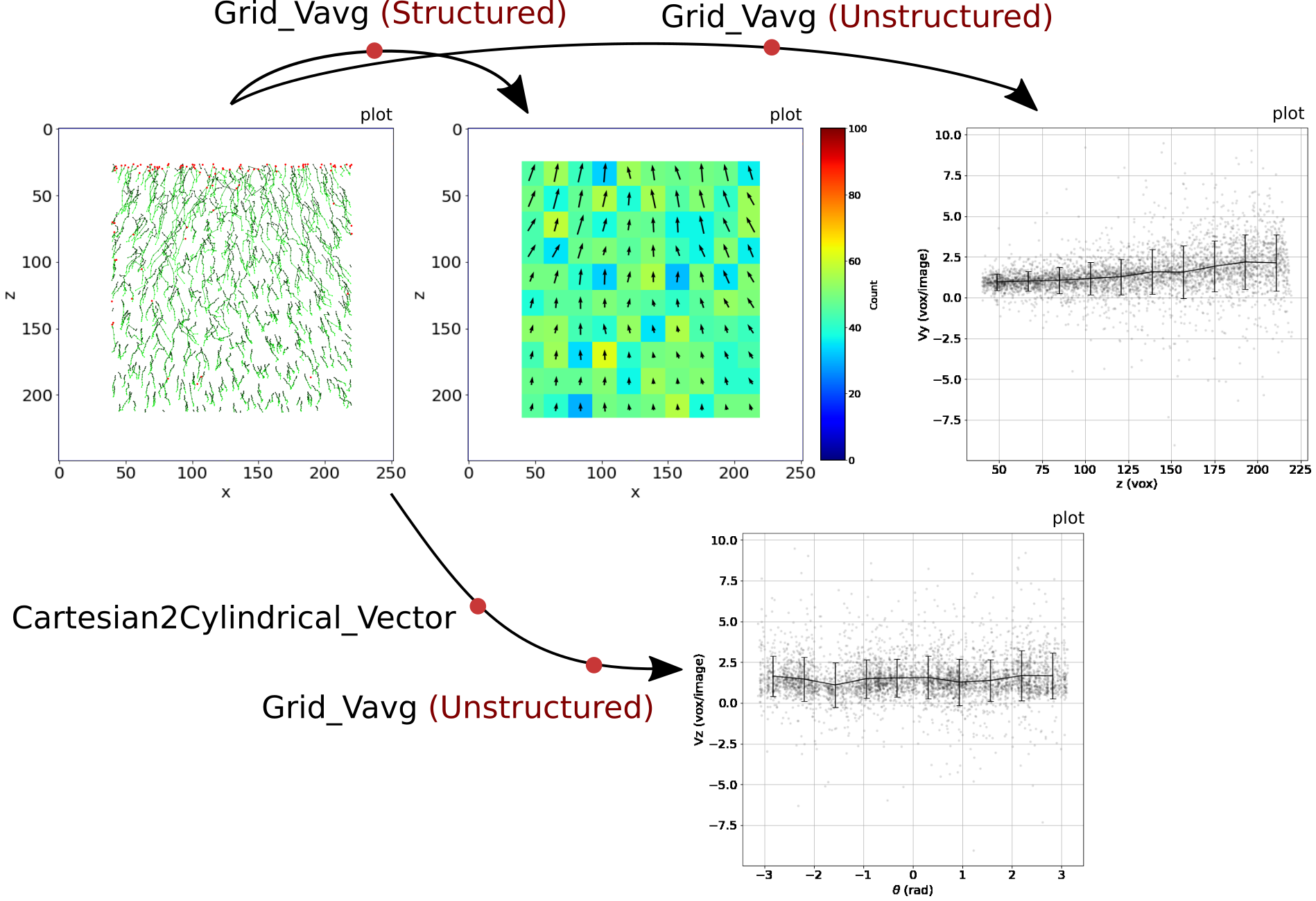

Passage and Average

Functions to convert scalar, vectorial or tensorial properties from cartesian to cylindrical and spherical, and perform time/space averages.

In this example the displacement field is first expressed in a cylindrical basic and then averaged.

Two ways of measuring the internal strain field

Shape field, defined in [Graner2008] and first used in [Raufaste2015]

Texture field, defined in [Graner2008]

Label traking

The tracking method was inspired by ID-track presented in [Ando2013].

Tracking of five bubbles, showing various tracked properties: elastic internal strain, number of neighbours, velocity, and volume.

References

van der Walt et al., scikit-image: Image processing in Python. PeerJ 2:e453 (2014) https://doi.org/10.7717/peerj.453

Stamati et al., (2020). spam: Software for Practical Analysis of Materials. Journal of Open Source Software, 5(51), 2286, https://doi.org/10.21105/joss.02286

Andò,E. et al., Experimental micromechanics: grain-scale observation of sand deformation, Géotechnique Letters 2, 107–112, (2012) https://doi.org/10.1680/geolett.12.00027

Hall et al., Discrete and continuum analysis of localised deformation in sand using X-ray μCT and volumetric digital image correlation. Géotechnique, 60(5), 315-322, (2010) https://doi.org/10.1680/geot.2010.60.5.315

Graner et al., Discrete rearranging disordered patterns, part I: Robust statistical tools in two or three dimensions, Eur. Phys. J. E 25, 349–369 (2008) https://doi.org/10.1140/epje/i2007-10298-8

Raufaste, C. et al., Three-dimensional foam flow resolved by fast X-ray tomographic microscopy, EPL, 111, 38004, (2015) https://doi.org/10.1209/0295-5075/111/38004

Schott et al., Three-dimensional liquid foam flow through a hopper resolved by fast X-ray microtomography, Soft Matter, (2023) https://doi.org/10.1039/d2sm01299e